(419) 873-8300

3-Strand Rope Vs. Braided Rope

Rope, like most things, is made in many shapes, sizes, and colors with a wide array of uses, but the production methods of this range of products are what really make the biggest difference to the consumer. To understand the differences between all of the ropes on the market, we must first understand their construction. All rope is either twisted or braided in some way with added variables such as different materials, protective coatings, or added strands for more complex braiding patterns. Nearly all twisted ropes have three strands, so let’s start there.

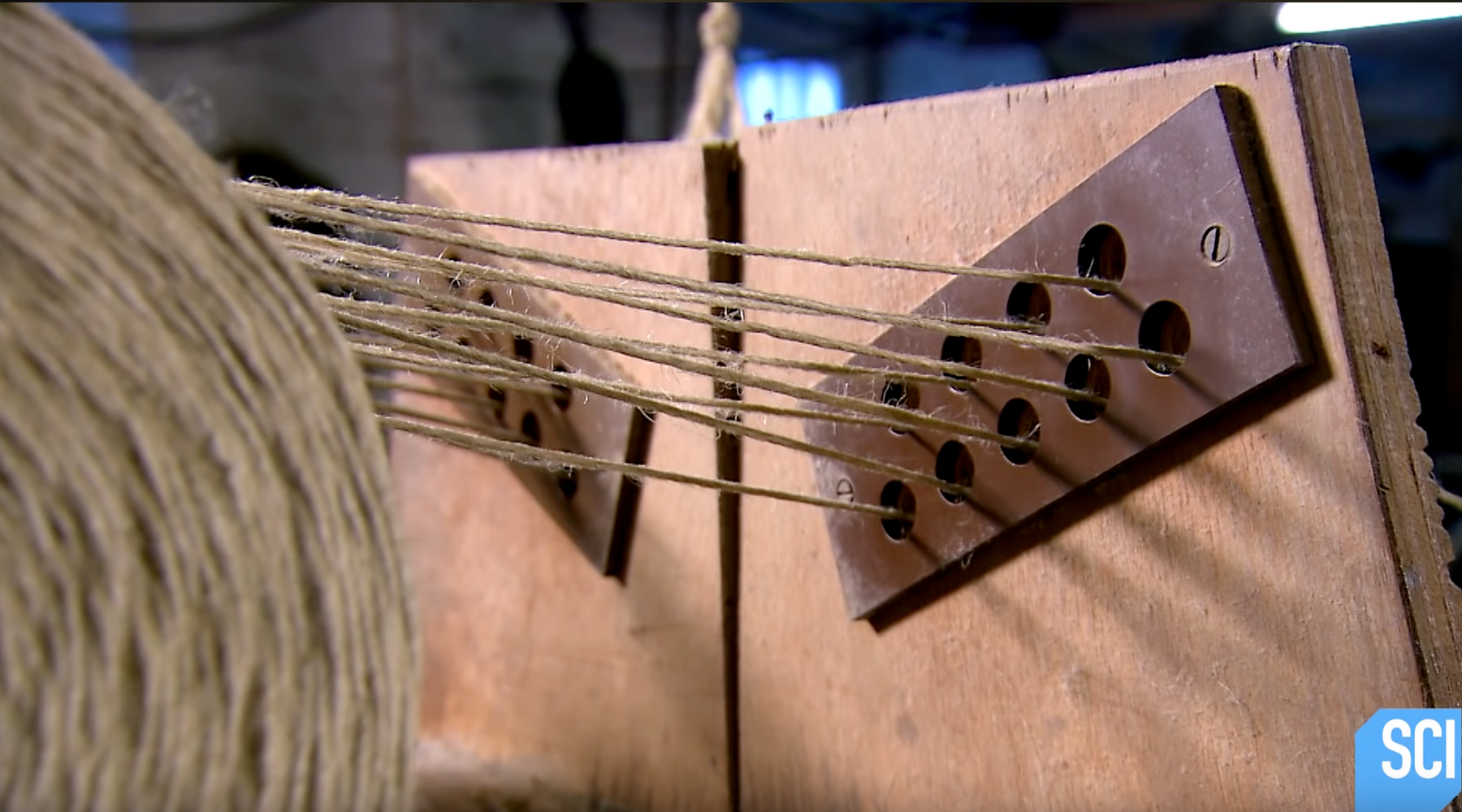

As one might assume, 3-strand is rather self-explanatory in its construction. Very small fibers or yarn are twisted evenly into one larger strand and pulled tight. Three of these strands are held together at a fixed point and twisted together once more until the entire length is uniform. Traditionally, this is done in long indoor areas up to 1000 feet long known as ropewalks, some of which are still in use. Thanks to the marvels of semi-modern technology, these same ropes can now be made in a much more economically size area. The final product will be considerably shorter than the initial strands, but the added strength is well worth it. This process also gives 3-strand rope its iconic barber pole or candy cane twisted appearance. You will most commonly find 3-strand rope in gymnasiums, landscape installations, and perhaps pirate ships, but with some of your own vision and creativity, 3-strand rope can be used any place you so choose (within reason).

Braided rope is a little more complicated than just a simple twist. Cylinders wrapped in small fibers or yarn, called “bobbins”, are placed onto a machine that intricately spins, weaves, and rotates the bobbins in and out of themselves like an elegant dance. All of the strands meet at a funnel above that eases the strands together as they are braided below. Out of the funnel, the rope is then ran through a pulley system with a good amount of tension to set the rope. For some synthetic ropes, the pulley system will run through a steam treatment pipe as a way to further set the fibers into place. After being set, the pulley maze ends at a rotating spool to gather up the finished rope just as fast as it can be braided. Braided rope has a smooth feel, round shape, and the capability to be incredibly strong, making it optimal for climbing, boating, macramé, and just about anything else you could tie up.

Those are the basics of twisted and braided rope, but there are some noteworthy combinations possible. Double braid ropes have a braided core with a jacket braided around it. To further the complexity, some arborist climbing lines have a 3-strand twisted core inside a braided core wrapped in a braided jacket. All ropes, twisted or braided, have their purpose, but not all ropes are created equally. Different ropes are made for different reasons, so make sure you find the one that’s right for your job, hobby, or decorative art piece.

Knot & Rope Supply

Rope has been made out of plant fibers for centuries, even though synthetic options are also available.

How the rope is made.

The process from start to finish, with some testing too.